How Our System Improved Fleet Operations and Reduced Costs for Pabari Transport

Client

Pabari Transport

Services

Fleet Management System

Industry

Transportation & Logistics

Project Summary

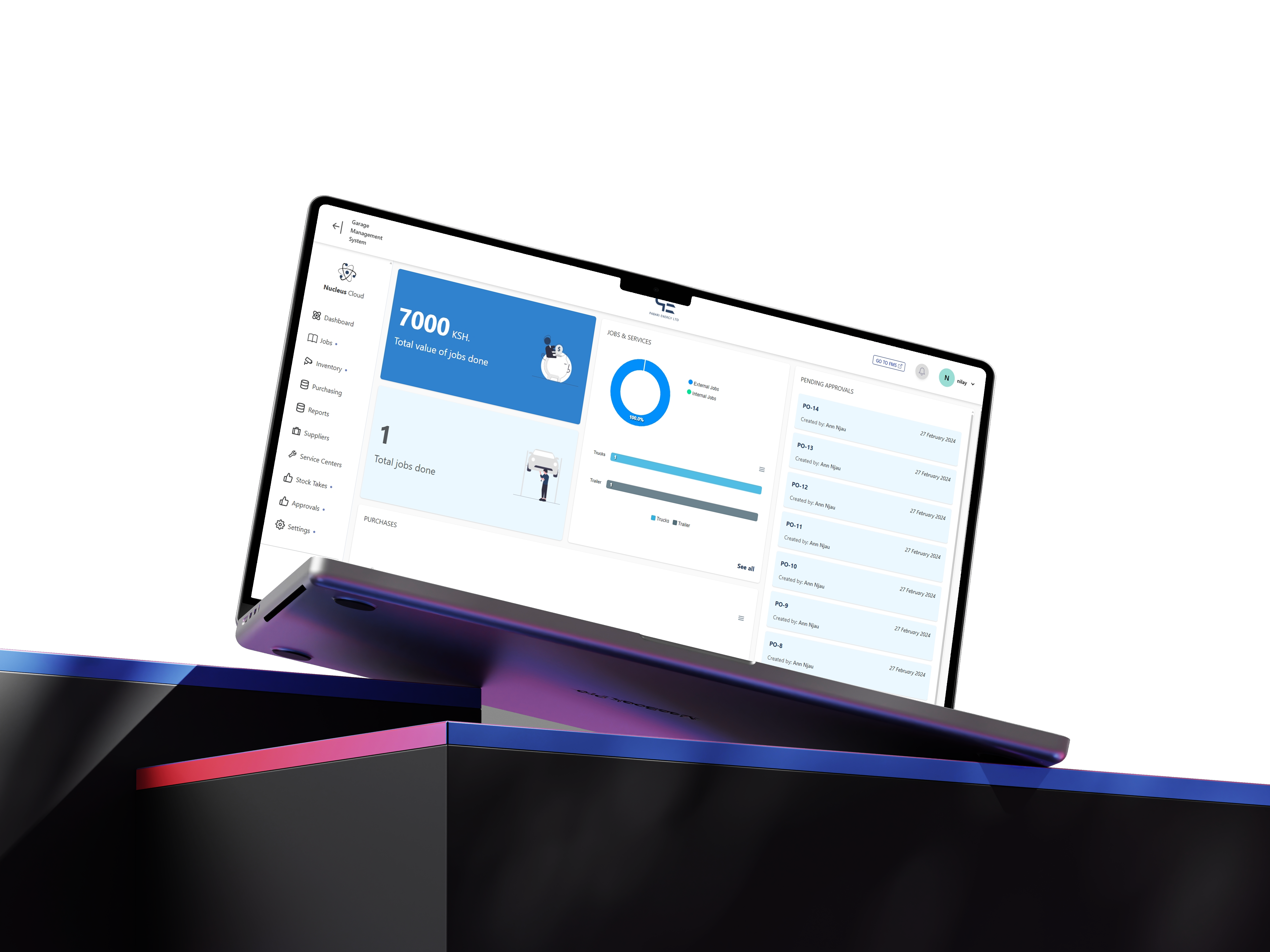

We implemented an Inventory and Garage Management System for Pabari Transport that increased their vehicle utilization by 35% and significantly reduced their maintenance costs. The system replaced manual workshop processes with digital tracking and improved their procurement efficiency.

The Client

Pabari Transport is a major transportation company in East Africa, operating a large fleet of vehicles for logistics operations across multiple countries. They handle daily deliveries that require consistent vehicle availability and minimal maintenance downtime.

The Challenge

Pabari Transport faced four specific operational problems:

Workshop Management Issues

Inefficient Parts Procurement

Poor Fleet Scheduling

Inventory Control Problems

The Solution

Workshop Management System

Procurement Management System

Inventory Control System

Business Impact

Measured Improvements

Cost Reductions

System Benefits

Operational Benefits

Conclusion

The Inventory and Garage Management System solved Pabari Transport's specific operational challenges by providing clear tracking of repairs, maintenance, and parts inventory. The 35% improvement in vehicle utilization directly resulted from better maintenance scheduling and reduced downtime. The system continues to help Pabari Transport manage their fleet more efficiently and maintain better control over their operational costs.